no data

CNC Solution

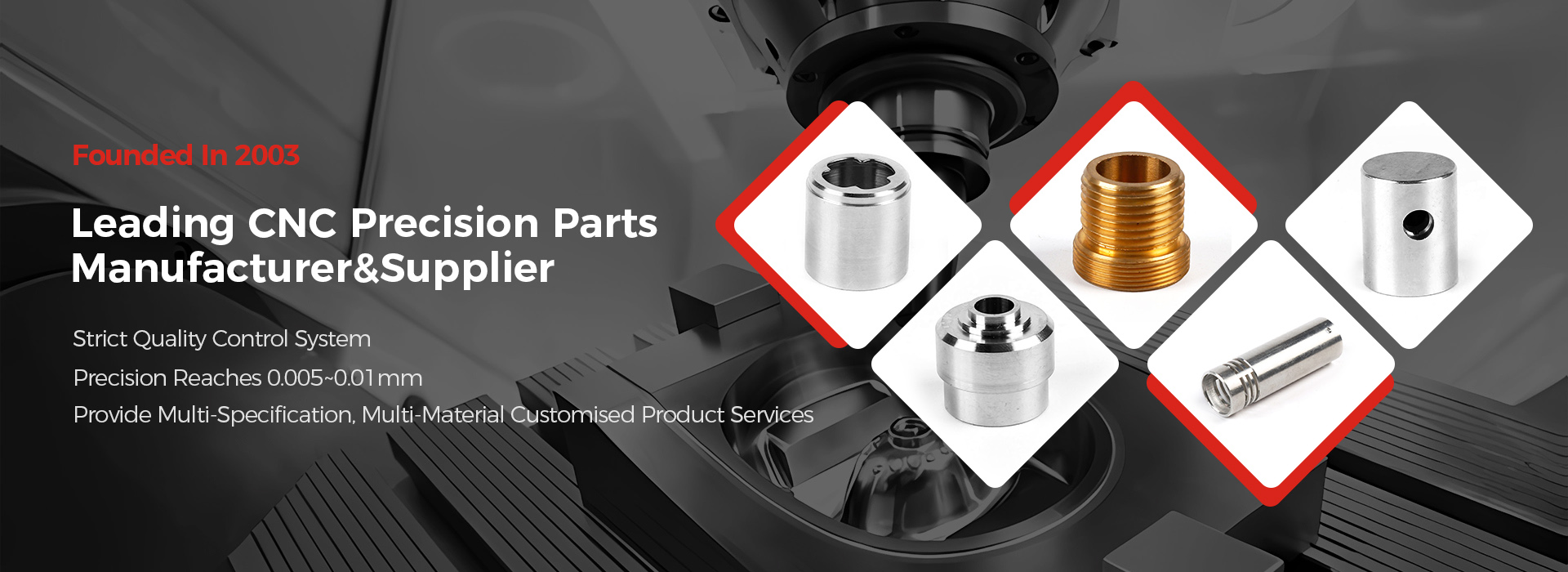

High precision, high wear resistance, and the ability to machine parts of specific shapes, including various cutting operations such as drilling, boring, tapping, and knurling, play a vital role in many fields such as medical devices, precision instruments, sporting goods, and automobile manufacturing.

no data

no data

no data

Our Service

Industry Applications

STEP-Your Partner for Metal Parts Manufacturing & Supply

STEP's products are widely marketed abroad, particularly in Europe, North America, and Southeast Asia. The company has established a good reputation and broad market and has gained the trust of well-known enterprises such as Jabil, Whirlpool, Siemens, Electrolux, F&D, Philips, and JOHNSON ELECTRIC.

no data

Why Choose STEP

Machines: 58 sets of Taiwan Ming Yang CNC automatic lathes, 26 sets of CNC numerical control lathes and 19 sets of CNC machining centres.

Provide multi-specification, multi-material customised product services.

Precision reaches 0.005~0.01mm.

Strict quality control system to control the defective rate.

no data

our Factory

20 years of experience in high-end metal parts customization. Own 66 precision punching machines, 25T~300T. Professional production provides high-quality products and services, competitive prices and excellent customer service.

no data

Our Partners

In the future, STEP aims to provide more customers with quality products and satisfactory services.

no data

Enterprise certificate

Our dedication to achieving and maintaining these certifications reflects our ongoing efforts to continually improve our business processes and enhance customer satisfaction.

no data

Interested In Partnering On A Custom Metal Stamping Production Project? Contact us to get the best quote

Official email:rita.zi@step-metalwork.com

Official email:rita.zi@step-metalwork.com

High-end Metal Parts Costomizing for 20 years.Product processing precision is high, production capacity is large, quality is stable, delivery capacity is strong, Reliable Quality – ISO9001 certified + 100% inspection, defect rate <0.3%. Responsive Service – 1-hour quotation, 8-hour solution proposal!

Copyright © 2025 STEP Metal and Plastic Technology Co., LTD | Sitemap Privacy policy