20+ Years Expert in Custom Metal Stamping and CNC Machining

How Round Aluminum Heat Sinks Can Enhance System Performance and Reliability

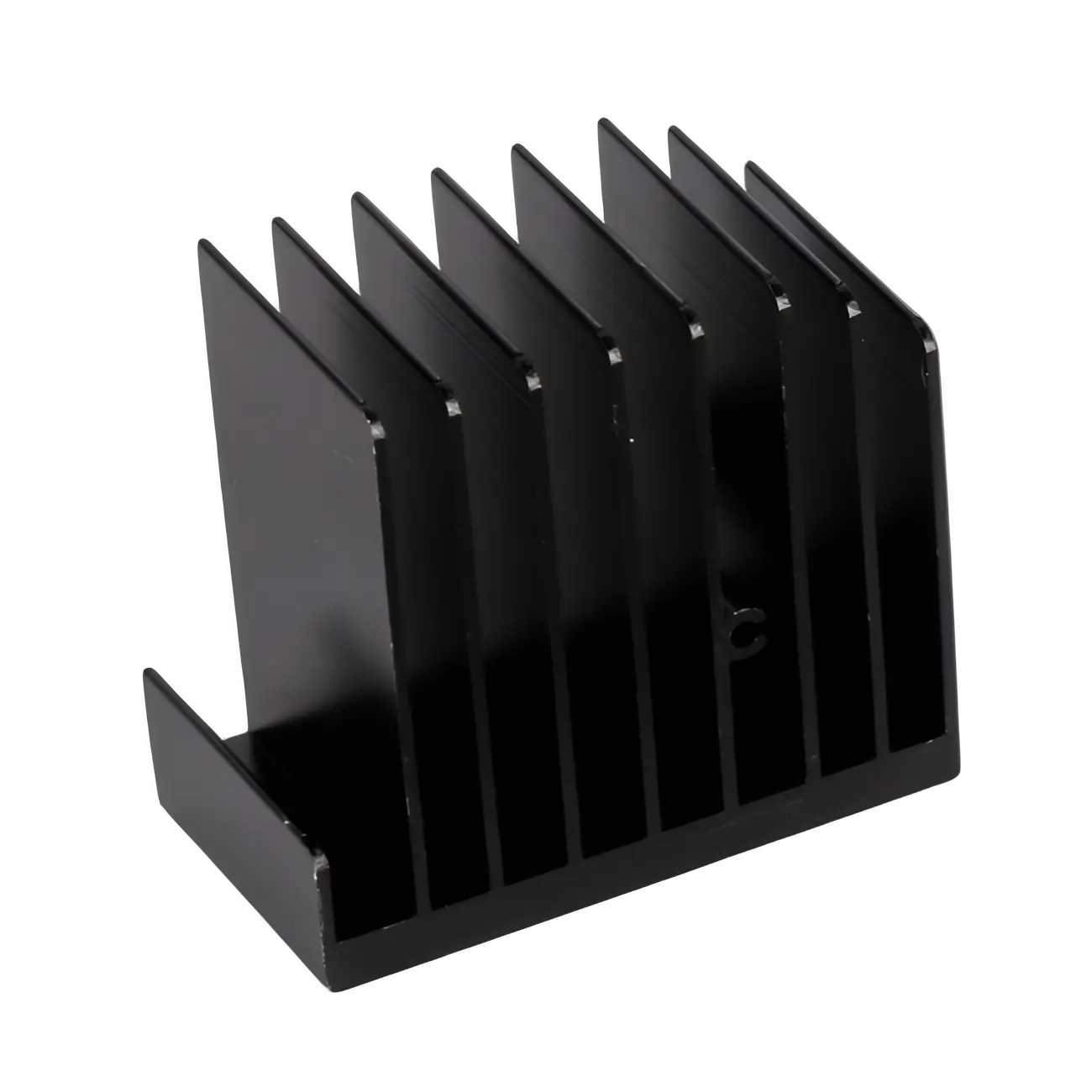

Thermal management is a critical factor in ensuring the optimal performance and longevity of electronic systems. Heat sinks play a vital role in managing this thermal load by transferring heat away from components. Among the various types of heat sinks available, round aluminum heat sinks stand out for their unique advantages. These cylindrical-shaped heat sinks, typically made from aluminum alloys such as 1050, 3003, or 6061, offer a balance of thermal conductivity and mechanical strength. The extrusion process shapes the metal into a continuous cylindrical form, followed by cutting and finishing to create an array of fins.

The choice of aluminum alloy is crucial for optimal thermal performance. Aluminum 1050 is highly pure but has the lowest thermal conductivity, whereas 6061 offers a better balance between strength and thermal properties. The extrusion process allows for precise fin spacing and thickness, enhancing the heat sinks efficiency. Surface treatments, such as anodizing, further improve durability and thermal conductivity. The round profile of these heat sinks offers several advantages over rectangular designs, including maximizing surface area relative to the volume, reducing turbulence, and promoting laminar flow.

Effectiveness of Round Aluminum Heat Sinks in Thermal Management

When compared to rectangular heat sinks, round aluminum heat sinks offer superior thermal performance. A study by the Journal of Heat Transfer found that round heat sinks can dissipate up to 20% more heat than their rectangular counterparts, thanks to their streamlined design. This enhanced performance is due to the optimization of surface area and the reduction of turbulence, which promotes more efficient heat transfer.

The heat transfer process in round aluminum heat sinks involves both convection and conduction. The fins create a large surface area for air to flow over, enhancing natural convection. Solid metal construction facilitates efficient conduction of heat from the component to the fins, where it is then radiated into the surrounding air. This comprehensive approach ensures that heat is dissipated more effectively, maintaining optimal operating temperatures for electronic components.

Enhancing System Reliability with Round Aluminum Heat Sinks

Effective thermal management is not only about dissipating heat but also about maintaining optimal operating temperatures for critical components. By ensuring that components remain cool, round aluminum heat sinks contribute to improved performance and reduced thermal stress. This is particularly crucial in high-performance electronics where excessive heat can lead to performance degradation and failure.

Case Study: Benefits in Server Environments

A case study conducted by a leading data center provider demonstrated that the implementation of round aluminum heat sinks in server racks significantly improved system reliability. Servers operating at optimal temperatures experienced a 30% reduction in downtime and a 25% increase in overall system uptime. Maintenance costs for these servers also decreased by 20%, highlighting the long-term benefits of using round aluminum heat sinks. These results underscore the importance of effective thermal management in critical systems.

Practical Applications of Round Aluminum Heat Sinks

Round aluminum heat sinks are widely used in various industries, including consumer electronics, automotive, and industrial sectors. In consumer electronics, they help keep smartphones, laptops, and gaming consoles running at optimal temperatures. In the automotive industry, they are essential for power electronics and climate control systems. In industrial settings, they are used in motor control systems, HVAC units, and other high-power devices.

Real-World Success Stories

Two notable examples of successful integration are in the aerospace and automotive industries. In the aerospace industry, aluminum heat sinks are used to manage the heat generated by avionics and navigation systems. In the automotive sector, round aluminum heat sinks are part of the thermal management solutions for electric vehicle batteries and motor controls. These applications demonstrate the versatility and effectiveness of round aluminum heat sinks across different industries.

Performance Metrics and Measurement

To assess the effectiveness of round aluminum heat sinks, several metrics are commonly used, including thermal resistance, heat flux, and dissipation capacity. Thermal resistance () is a measure of a heat sinks ability to transfer heat from a component to the surrounding air. Lower thermal resistance values indicate better heat transfer.

Methods for Testing and Measuring Heat Sink Effectiveness

Testing methods include using thermal sensors to measure the temperature difference between the component and the ambient air. Convection calorimeters are often used to simulate real-world thermal conditions and accurately measure heat sink performance. For instance, a series of tests conducted by the Department of Energy found that round aluminum heat sinks demonstrated an average thermal resistance of 0.04C/W, compared to 0.05C/W for rectangular designs.

Future Trends and Innovations in Heat Sink Design

As technology advances, so do the designs and fabrication processes for heat sinks. Innovations such as hollow extrusions, micro-channel heat sinks, and 3D-printed heat sinks are poised to revolutionize the industry. These technologies offer new opportunities for optimizing thermal performance and reducing material usage. Sustainable advancements, such as using recycled aluminum and developing biodegradable coatings, are also at the forefront of future developments.

Conclusion

Round aluminum heat sinks offer unparalleled advantages in thermal management, making them an essential component for enhancing system performance and reliability. Their unique design, superior thermal performance, and wide range of practical applications make them a go-to solution for various industries. As technology continues to advance, the role of round aluminum heat sinks in maintaining optimal operating temperatures will only grow more important. Investing in high-quality round aluminum heat sinks today can lead to significant long-term benefits, including improved system reliability, reduced maintenance costs, and enhanced overall performance.

STEP Metal and Plastic

Tel: +86-15595982795

Email:rita.zi@step-metalwork.com

Adress: Building1&2,No.3, Ma'an 2nd Road, Chashan Town 523382, Dongguan, Guangdong, China