20+ Years Expert in Custom Metal Stamping and CNC Machining

Precision Engineering in Aluminum Stamping Parts: Tips and Techniques

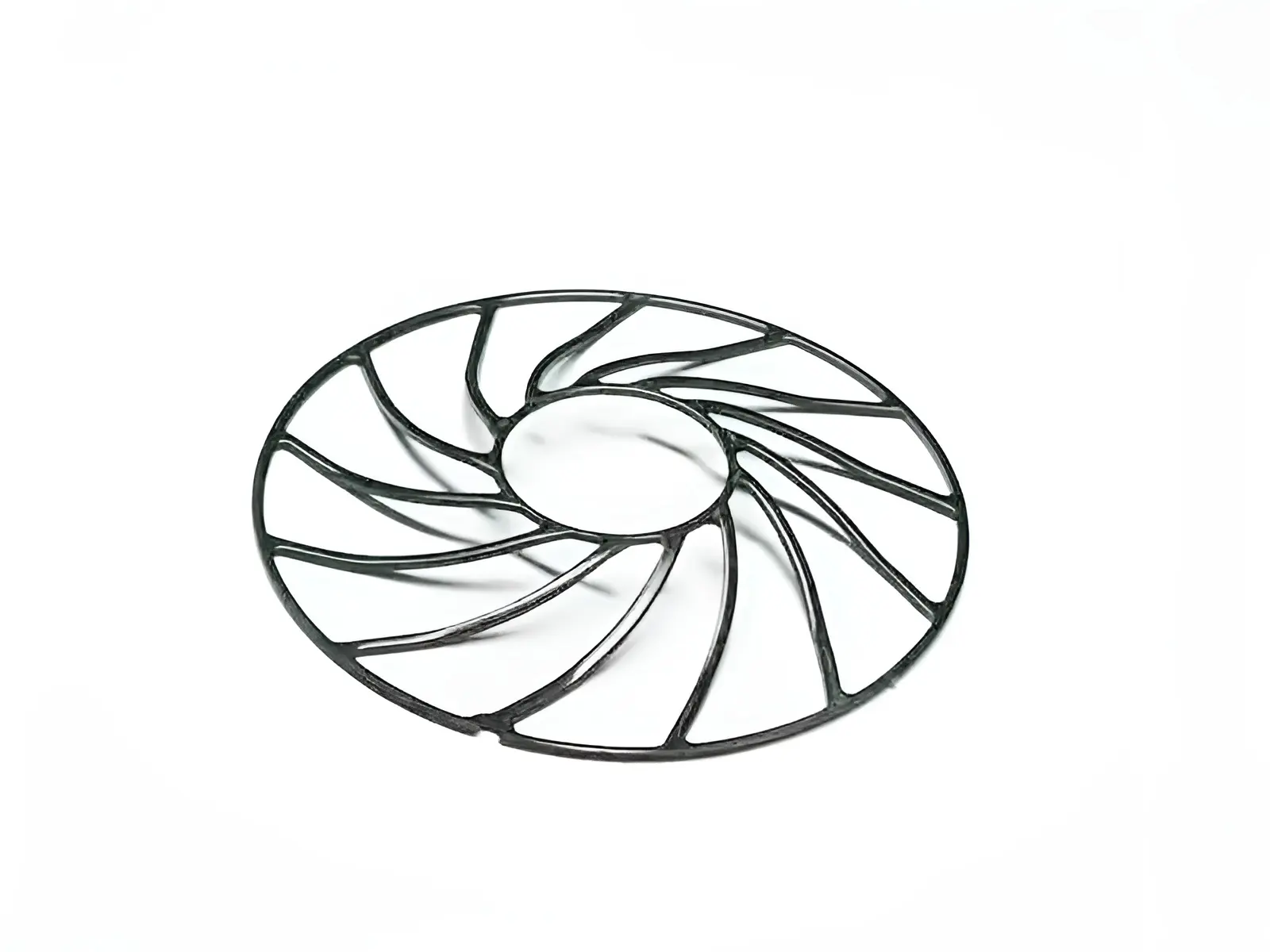

Aluminium stamping is a versatile manufacturing process that involves creating intricate shapes and patterns on aluminium sheets. It is widely used in industries where lightweight, durable, and high-strength materials are required. The versatility of aluminium makes it an ideal choice for stamping parts that need to be both functional and aesthetically pleasing.

One of the key advantages of aluminium stamping is its ability to produce complex geometries with high precision. Unlike other metals, aluminium is relatively lightweight, making it easier to create parts with thin walls and intricate designs. This makes it an excellent choice for applications such as automotive parts, where lightweight components are crucial for fuel efficiency and performance.

However, achieving high precision in aluminium stamping is not without challenges. The process requires meticulous planning, precise tooling, and a deep understanding of the material properties. Without the right approach, it is easy to encounter issues such as material thinning, springback, and surface defects. This is where precision engineering comes into play.

The Role of Precision Engineering in Aluminium Stamping

Precision engineering in aluminium stamping involves a combination of design, tooling, and manufacturing techniques aimed at achieving the highest level of accuracy and consistency. It is through this process that manufacturers can produce components that meet the stringent requirements of modern industries.

One of the first steps in precision engineering is the design and fabrication of the dies used in the stamping process. The design of the die must be precise to ensure that the stamped parts meet the desired specifications. This involves using computer-aided design (CAD) software to create detailed blueprints that guide the manufacturing process. Without precise dies, it is easy to produce parts that do not meet the required tolerances.

Once the dies are fabricated, the next step is the production of the aluminium stamping parts. This involves using high-quality stamping machinery equipped with cutting-edge tools and dies. The quality of the machinery and the maintenance regime play a crucial role in ensuring that the parts are produced with minimal defects.

Another critical aspect of precision engineering in aluminium stamping is the control of the stamping process. This involves monitoring various parameters such as temperature, pressure, and speed to ensure that the stamping process is optimal. Proper control of these parameters helps to prevent material thinning, which can lead to surface defects and reduced strength.

Finally, the finished parts are inspected for quality and defects. This involves using advanced inspection techniques such as X-ray and ultrasonic testing to ensure that the parts meet the required standards. Only parts that pass these inspections are considered for use in the final product.

The Benefits of Precision Engineering in Aluminium Stamping

Precision engineering in aluminium stamping offers a range of benefits that make it a preferred choice for manufacturers. These benefits include improved product quality, enhanced performance, and cost savings, among others.

One of the most significant benefits of precision engineering is the ability to produce high-quality products that meet the exacting requirements of modern industries. By ensuring that the parts are produced with minimal defects and maximum precision, manufacturers can reduce waste, improve efficiency, and deliver products that meet customer expectations.

Another benefit of precision engineering is the ability to enhance the performance and durability of the stamped parts. By controlling the stamping process and ensuring that the parts are made from high-quality materials, manufacturers can produce components that are more resistant to wear and tear. This is particularly important in industries such as aerospace and automotive, where the performance of the components can have a direct impact on the performance of the final product.

Precision engineering also plays a crucial role in reducing costs. By ensuring that the parts are produced with minimal waste and rework, manufacturers can reduce their production costs. Additionally, the use of advanced inspection techniques can help to identify and correct defects early in the production process, further reducing costs.

Finally, precision engineering contributes to the environmental sustainability of manufacturing processes. By producing high-quality, durable components, manufacturers can reduce their reliance on raw materials and lower their carbon footprint. This is particularly important in industries where sustainability is a key priority.

Tips for Achieving Precision in Aluminium Stamping

Achieving precision in aluminium stamping requires a combination of skilled craftsmanship, advanced technology, and a thorough understanding of the process. The following tips can help you achieve excellence in your aluminium stamping projects.

Design for Precision: The design of the dies and tools used in the stamping process is critical to achieving precision. Use CAD software to create detailed blueprints that guide the manufacturing process. Ensure that the dies are fabricated to the highest standards to minimize variability in the final product.

Use of High-Quality Tooling: The quality of the tooling used in the stamping process is a key factor in achieving precision. Invest in high-quality Dies and stamping machinery to ensure that the parts are produced with minimal defects.

Process Control: Proper control of the stamping process is essential for achieving precision. Monitor the temperature, pressure, and speed of the stamping machine to ensure that the process is optimized. Adjust these parameters as needed to achieve the desired results.

Regular Maintenance and Inspection: Regular maintenance and inspection of the stamping machinery and dies can help to ensure that they are in optimal condition. This can help to prevent wear and tear and ensure that the parts are produced with minimal defects.

Training and Certification: Precision engineering in aluminium stamping requires a high level of technical expertise. Ensure that your team is properly trained and certified to handle the complexities of the process. This will help to ensure that the parts are produced with the highest level of precision.

Advanced Techniques in Precision Engineering for Aluminium Stamping

In addition to the basic principles of precision engineering, there are several advanced techniques that can be employed to further enhance the quality and efficiency of aluminium stamping processes.

Integration of CAD and CAM Software: The integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software can help to optimize the stamping process. CAD software is used to create detailed blueprints, while CAM software is used to generate toolpaths for the stamping machinery. By integrating these tools, manufacturers can produce parts with minimal waste and maximal efficiency.

Use of 3D Printing for Tool Design: The use of 3D printing technology can help to create complex and customised dies and tools for the stamping process. This can help to reduce production costs and improve the quality of the parts.

Continuous Improvement and Process Optimisation: Precision engineering is not a one-time activity but an ongoing process. Manufacturers should adopt a mindset of continuous improvement and optimise their stamping processes on an ongoing basis. This can help to ensure that the parts are produced with the highest level of precision and efficiency.

Case Studies and Real-World Applications: Case studies and real-world applications can provide valuable insights into the practical implementation of precision engineering in aluminium stamping. By studying successful projects, manufacturers can learn from best practices and apply them to their own operations.

Overcoming Common Challenges in Precision Engineering

Despite the best efforts, achieving precision in aluminium stamping can be challenging. There are several common challenges that manufacturers may face, including material inconsistencies, tooling wear and tear, and surface finish issues. The following strategies can help to address these challenges and ensure that the parts are produced with the highest level of precision.

Material Selection: The selection of the right material is crucial for achieving precision in aluminium stamping. Choose materials that have the right properties, such as strength, conductivity, and corrosion resistance, to ensure that the parts are durable and reliable.

Tooling Management: Poor tooling management can lead to variability in the final product. Implement a tooling management system that allows for the regular maintenance and inspection of dies and tools. This can help to prevent wear and tear and ensure that the parts are produced with minimal defects.

Surface Finish and Edging: Achieving a smooth and even surface finish is essential for the functionality and aesthetics of aluminium stamping parts. Use finishing techniques such as electroplating or laser cutting to achieve a high-quality surface finish. Pay attention to edge quality to ensure that the parts meet the required specifications.

Waste Reduction and Process Optimisation: Reducing waste and optimising the stamping process can help to improve efficiency and reduce costs. Implement process optimisation techniques such as lean manufacturing to eliminate unnecessary steps and reduce production time.

The Future Trends in Precision Engineering for Aluminium Stamping

The future of precision engineering in aluminium stamping is looking promising, with several emerging technologies and trends on the horizon. These trends are driven by the need for higher efficiency, greater sustainability, and greater precision in manufacturing.

Emerging Materials: The development of new materials, such as advanced high-strength aluminium alloys, is set to revolutionise the aluminium stamping industry. These materials offer higher strength, better conductivity, and improved corrosion resistance, making them ideal for a wide range of applications.

Automation and Digitalisation: The integration of automation and digitalisation into the stamping process is expected to further enhance precision and efficiency. Automated stamping machines and systems that use AI and machine learning can help to reduce human error and improve the accuracy of the stamping process.

Sustainability: As environmental concerns become increasingly important, manufacturers are looking for ways to reduce their carbon footprint and improve sustainability. Precision engineering in aluminium stamping can play a key role in achieving this by producing high-quality, durable components that require less raw material and energy to produce.

Industry Growth: The aluminium stamping industry is set to grow significantly in the coming years, driven by the increasing demand for lightweight and high-performance components in industries such as aerospace, automotive, and renewable energy. Precision engineering will be key to meeting this demand and ensuring that the parts meet the highest standards of quality and performance.

Achieving Excellence in Aluminium Stamping

In conclusion, precision engineering in aluminium stamping is essential for producing high-quality, durable, and efficient components that meet the demands of modern industries. By adopting advanced techniques, overcoming common challenges, and staying ahead of emerging trends, manufacturers can achieve excellence in their aluminium stamping operations.

STEP Metal and Plastic

Tel: +86-15595982795

Email:rita.zi@step-metalwork.com

Adress: Building1&2,No.3, Ma'an 2nd Road, Chashan Town 523382, Dongguan, Guangdong, China